Intro to Selective Pallet Rack

New to pallet rack? We’re going to cover the fundamentals of selective pallet rack and give you the confidence to get started with your project. At a basic level, pallet rack is a storage system usually made up of three parts: beams, frames, and wire decks or pallet support bars. Upright frames hold the beams in place, which in turn stabilize the upright frames. Wire decks and pallet support bars make pallet rack safer and easier to use by creating extra support and surface area for inventory. These three parts work together to provide a heavy-duty storage solution that countless businesses depend on to organize their inventory.

Now you have a basic understanding of pallet rack, but we’re not done yet. To become a pallet rack expert, we’ll need to dig a little deeper. In this article, we’re going to get a better knowledge of pallet rack components, accessories, and installation. We’ll also answer questions about used pallet rack and whether or not selective pallet rack is the best fit for you.

Let’s start off with the three parts of selective pallet rack we mentioned earlier: pallet rack beams, frames, and wire decks.

Pallet Rack Beams

Beams are the components that lie horizontally, connecting the two upright frames. There’s a wide range of beam sizes available, with the most popular length being 96”. The reason 96″ beams are so popular is that they’re the perfect length for holding two standard GMA pallets side-by-side.

At Pallet Rack Now we carry both Ridg-U-Rak and Steel King pallet rack beams, as well as a big selection of used pallet rack brands. New pallet rack beams are usually painted with a bright orange finish, allowing forklift drivers and warehouse personnel to easily see each beam level. Most modern beams have an automatic locking device in place that keeps the beam from being dislodged from the frame. For beams that don’t have this feature, we recommend using pallet rack drop pins or the most appropriate pallet rack clip for the beam.

Pallet Rack Frames

Frames form the backbone of a selective pallet rack system, holding up the beams and wire decking. Our selective pallet rack frames are “teardrop style,” the most popular pallet rack slotting design. Teardrop pallet rack gets its name from the upside-down teardrop-shaped slots that are cut out of the frame columns. These cutouts are where the pallet rack beam connectors lock into the frames. Having these holes all the way up and down the frame lets users choose the beam level height and allows for easy re-slotting. Frames come in many sizes, so we recommend working with a Pallet Rack Specialist to determine the height that’s best for your application.

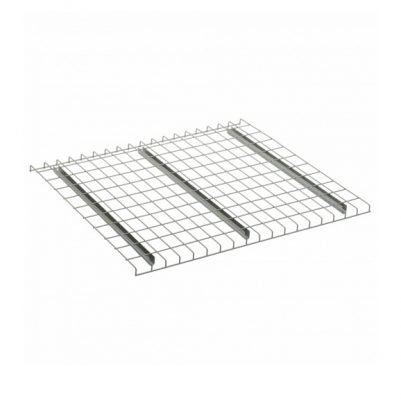

Wire Decks

Wire decks sit on top of pallet rack beams and provide a surface on which inventory can sit. Because beams alone provide very little surface area, wire decks make loading and unloading dramatically easier for forklift operators. A standard wire deck has between two and four support channels that give the deck its strength. The most common wire deck size is 42” deep x 46” wide, which is the size needed to hold one standard GMA pallet. Wire decks may have U-shaped channels for standard step beams or flare-shaped channels for beams without a step. Although wire decks typically come in either a painted gray or galvanized finish, they can also be painted in a wide range of custom colors.

Pallet Rack Accessories

Next, we’ll move on to pallet rack accessories. While the word “accessory” implies that these parts are unnecessary or extra, this couldn’t be further from the truth. Pallet rack accessories work to make selective pallet rack safer by protecting and stabilizing the rack structure. Below is a list of some of the more common pallet rack accessories along with short descriptions.

Pallet Support Bar:

An alternative to wire decking, two safety bars per pallet position help support pallet loads and stabilize cross beams. This option is more cost-effective than wire decking but more durable and sturdy than plywood.

Standard Column Protector:

Column protectors safeguard your pallet rack investment by forming a protective barrier around upright frame columns. This barrier deflects forklift tines, which are the primary cause of damage to frame columns. By protecting against forklifts, column protectors keep uprights strong and lengthen the lifespan of your pallet rack. For a hardware-free, extra-strength version of the standard column protector, consider the RamGuard column protector.

Wall Tie:

The higher the height-to-depth ratio of your pallet rack frames is, the less stable they are. To combat this problem, wall ties connect upright frames to an adjacent wall or other stable structure, providing an additional anchor point.

Row Spacer:

Row spacers connect two rows of back-to-back pallet rack. The reason why connecting back-to-back rows is important is that it stabilizes both rows. For frames that exceed the RMI recommended height-to-depth ratio of 6:1, row spacers can be used to effectively double the depth of the row by anchoring it to an adjacent row.

Shim:

When installing pallet rack frames, it’s important to have a level surface with which to work. If a level surface isn’t available, we advise using pallet rack shims to even out the connection between footplate and floor. Slipping this thin piece of metal between the footplate of your racking and the ground will provide added safety where uneven.

Used Pallet Rack

If you’re moving warehouses, need some extra racking, or are trying to save on costs, used pallet rack might be the right option for you. With high-quality used pallet rack, you can organize your inventory and maximize your warehouse space for a fraction of the cost you’d pay for new pallet rack. However, used pallet rack isn’t the best option for everyone. If the appearance of your pallet rack matters or a product warranty is important to you, you’re likely better off going with new product. If you’re unsure about whether to opt for new or used pallet rack, give us a call and we’ll be happy to help.

The used pallet rack we stock is hand-inspected and at our Maple Grove, Minnesota location. We have a large variety of different manufacturers and styles in stock. We ship across the country and always do our best to provide the best combination of competitive pricing and excellent customer service.

Used pallet rack