When helping customers find the right pallet racking for their storage needs, one of the first questions we invariably ask is how much they need each beam level to be able to hold. Knowing how much a customer needs their pallet rack beams to be able to hold is a highly valuable piece of information. Pallet rack beam level capacities vary by manufacturer, beam length, beam height, steel gauge, and other factors, and every application is unique.

Beam capacities may be easier to understand than the capacities of upright frames, but it’s still helpful to take a closer look at how beam capacities work. Doing so will help to fully understand the underlying variables. Once you’re familiar with the basics of pallet rack beams and their capacities, you can apply this knowledge in future applications.

Pallet Rack Beam Capacities

Whether ordering pallet rack beams online or getting a quote, the vendor will often provide the beam’s capacity rating if it’s an unused product (guaranteed capacities probably won’t be provided for used pallet rack). This number represents the weight that a pair of beams can safely hold – not the strength of a single beam. Even if you’re quoted a single pallet rack beam, the capacity rating shown on the quote applies to a pair.

When pallet rack beam capacity ratings are determined, they’re done so assuming a uniformly-distributed load (UDL). A UDL is a load that is evenly spread over the surface by which it’s supported. This is in contrast to, for example, a point load, in which the weight is concentrated in a smaller surface area. Because weight distribution affects capacity, pallet rack beam and wire deck capacities are usually rated for uniformly-distributed loads.

What is a Pallet Rack System?

A pallet rack system, simply put, is a unit or bay of racking. A single bay consists of two pallet rack frames and at least two beam shelf levels for structural integrity (two beams per level). All bays of racking are pallet rack systems.

Uniformly-distributed loads, or UDLs, are loads that are spread evenly across the supporting surface.

Beam Deflection

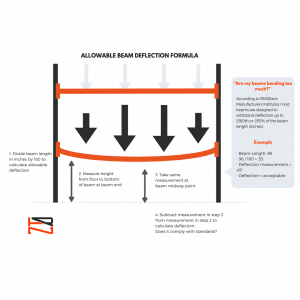

Beam deflection refers to the bowing out of beams that can happen when stressed by heavy loads. While beam deflection looks scary, some amount of beam deflection is normal. According to RMI, beams are usually designed to accommodate deflection up to .55% of the beam’s length. To figure out what the allowable deflection is for your beams, take the beam’s length and divide it by 180. For a 96” beam, that comes to .53” of allowable deflection.

To then determine whether or not your current deflection falls within the acceptable range, measure the beam’s distance from the floor at the very end of the beam and at the middle of the beam. If the difference in distance is less than .53”, you’re good to go. If not, your beams may be overloaded. Remember to consult a material handling professional if you have any questions about beam deflection in your application.

Wire Decks, Pallet Support Bars, and Beam Ties

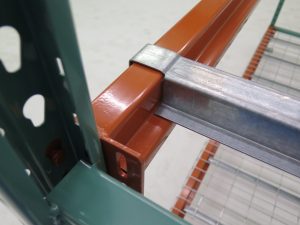

Load distribution isn’t the only factor that can affect beam capacities. Wire decks, pallet support bars, and beam ties have the ability to increase beam capacity by decreasing beam deflection. How much of a difference these components have on beam capacity can vary significantly by product type and manufacturer. We always recommend talking to your material handling vendor or the product’s manufacturer to verify safe capacities.

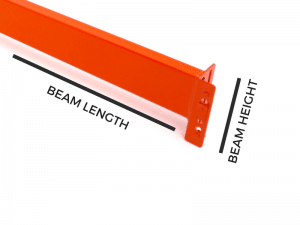

Beam Length vs Beam Height

It can sometimes be confusing for new customers to hear pallet rack beam terminology. There’s a good chance the customer will hear the seller refer to “beam length” and “beam height,” or alternatively “beam profile.” Beam length simply refers to the length of the beam, not including the end connectors. The term “length” can be confusing at first since the beam length will ultimately form the width of a pallet rack section once assembled. The other important beam dimension in terms of capacity is height, also known as the profile. The height of the beam refers to its top-to-bottom measurement when horizontally-oriented. Typically, the greater a beam’s height at a given length, the greater its capacity. All else equal, a 4” x 96” beam will reliably be stronger than a 2.5” x 96” beam.

Apply Your Beam Capacity Knowledge!

Now that you have a foundation of beam capacity knowledge you’ll be able to have a more informed conversation with your material handling supplier. You’ll understand common terminology and will be able to ensure your requirements are met. You’ll know beam capacities are rated for UDLs and how to measure deflection. Most importantly, you can play an active role in keeping your warehouse safe by observing beam capacity ratings and never overloading pallet racking.

Are you planning to expand your warehouse storage? We’d love to help you get started. Click the link below or give us a call at 888-578-1579 to talk with a Pallet Rack Specialist today.

Get a quote for your next pallet rack project!