What is Wire Decking?

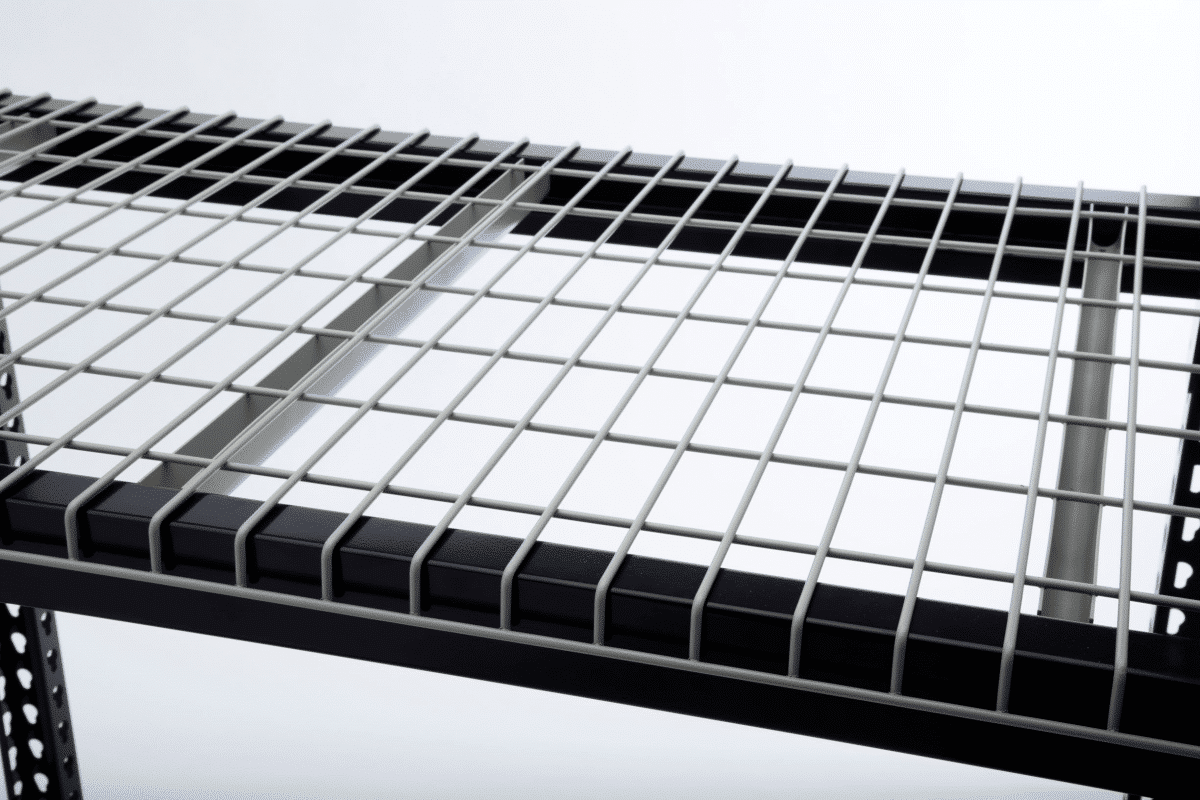

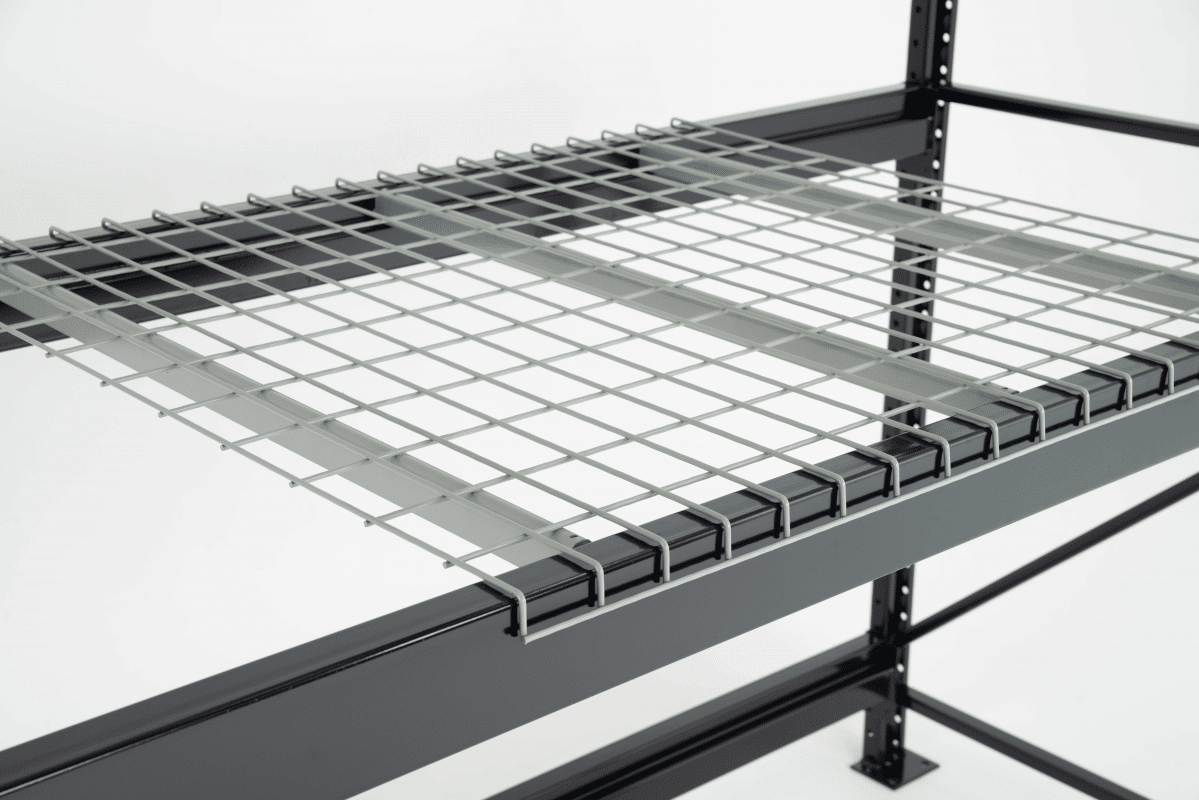

Wire decking is an essential part of any pallet rack configuration. At its simplest, this product is a wire mesh panel with channels welded beneath, providing capacity and stability. It creates a flat surface between beams to store pallets and products.

To meet fire codes and safety standards, many cities require mesh decking by law. If a fire were to arise, these decks allow sprinkler system water to fall through each level of decking directly to the source of the fire. Fittingly referred to as “fall-through.”

Types of Wire Decking

Now there are different types of wire decking. Read on to ensure you make the best choice for your specific pallet racking and storage purposes.

Double Waterfall

This style of wire decking for shelves includes a downturned edge on either side of the deck. These edges hook over the front and back pallet rack beams and sit securely on the shelf. Because of their unique design, double waterfall wire decks don’t require additional bolts or screws to be fully secured. These wire decks are the safest choice in case of a beam bowing out.

Up-Turned Waterfall

With one downturned edge and one up-turned edge, up-turned waterfall wire decking still provides stability and reduces shifting. The up-turned edge keeps products from falling off the back of the pallet rack system.

Inside Waterfall

Inside waterfall or drop-in decks are the same depth of the bay between beams. These wire decks drop in directly and sit flush on the beam step-downs. Since they don’t hug the beams like waterfall decks, they require tek screws to be fully secured. They are often used to label products and are great for storing smaller items that aren’t placed deep into the rack.

Flat Flush

Like inside waterfall decks, flat flush wire decking sits directly on the beam steps. However, these decks are less stable because their only point of contact with the beam is the channels themselves.

Sizes of Wire Decking

At Pallet Rack Now, we sell flare decks and step decks from two different wire deck manufacturers — Nashville Wire Products and J&L Wire. You can find any of the sizes below in either brand or style.

Channel Supports

Channel supports strengthen wire decks and help them sit securely on the pallet rack beams. Part of what differentiates one deck from another is the shape of its channel supports. There are many different channel styles but here are the most basic.

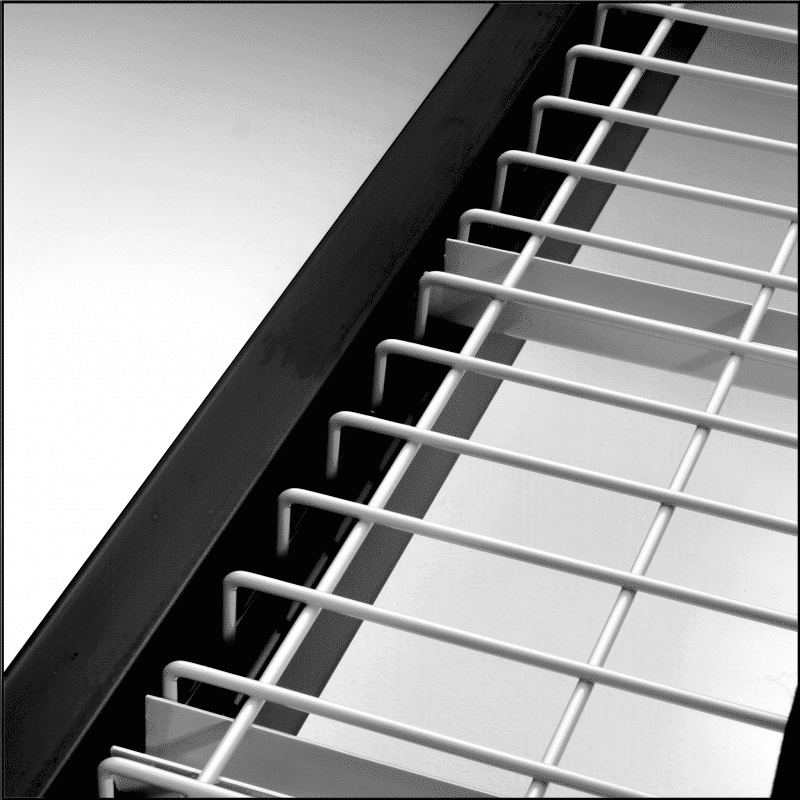

U-Channel

Wire decking with u-channel supports offers double support because the beam has two points of contact. The channels themselves sit on the beam step-downs while the decking rests atop the beams. U-channels can widen your storage options by offering a higher weight capacity with more stability.

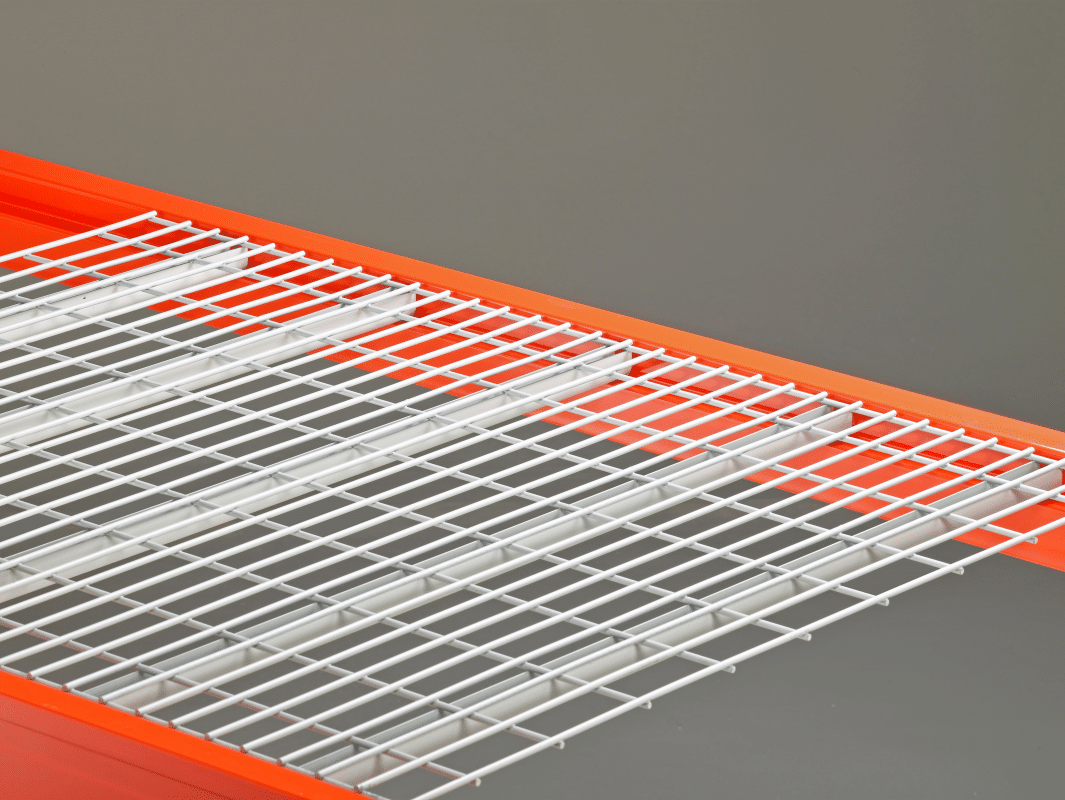

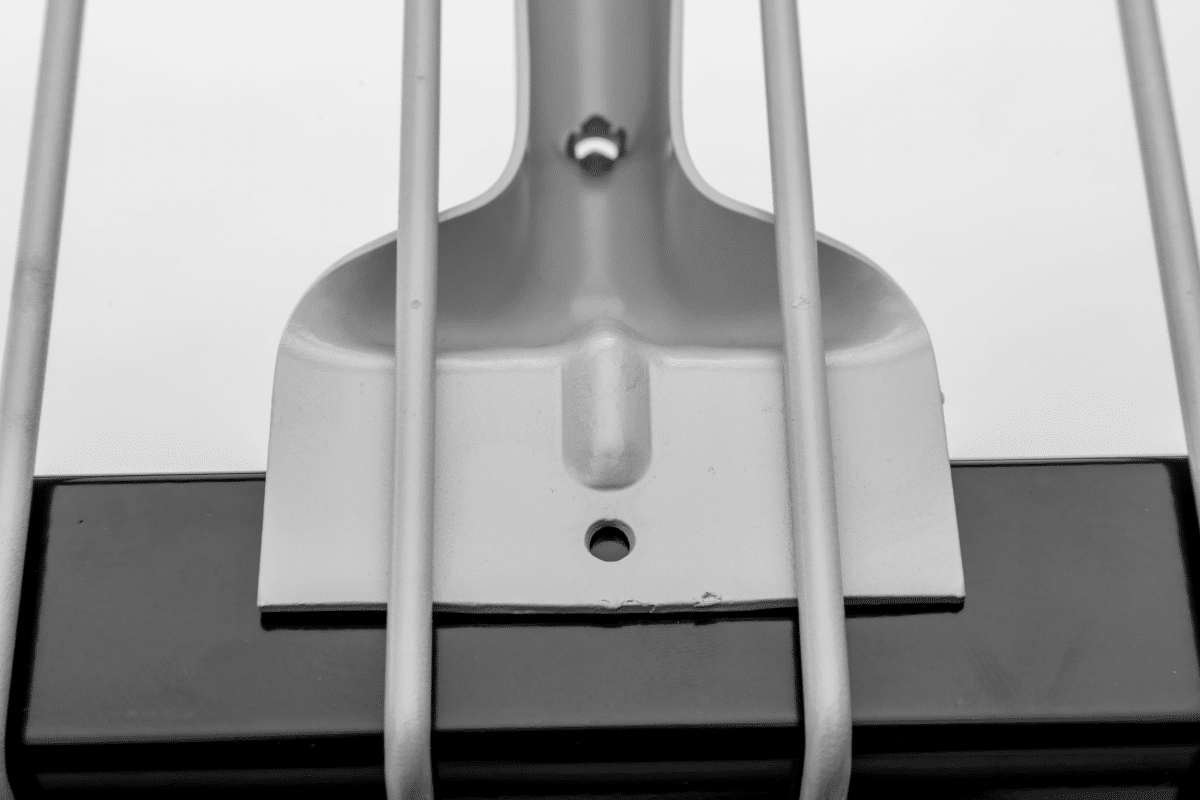

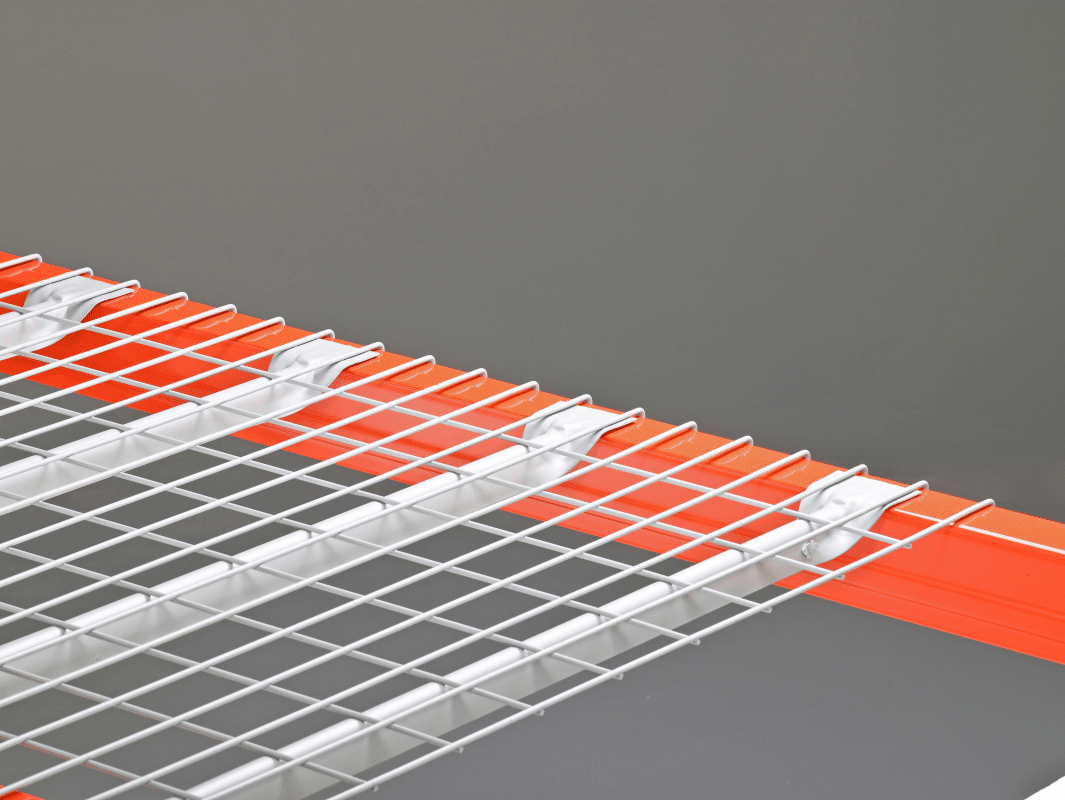

Flare-Channel

Flared channel supports rest directly on the beam without utilizing the beam steps. They offer less stability than u-channels but are a universal fit with box beams, structural beams, step beams, etc. Their universality makes them a more convenient choice of wire decking for shelves than many others.

Inverted U-Channel

Take a u-channel support, flip it upside-down, and you’ve created an inverted u-channel. Because inverted u-channels don’t collect dirt and debris like regular u-channels, they are great for food storage and other hygiene-dependent storage purposes.

Inverted Flare-Channel

These upside-down flared channel supports serve similar sanitary purposes to inverted u-channels but with a universal fit. They are often used in food handling and require less frequent cleaning.

Wire density plays a significant role in wire deck stability and capacity limits. The more wires, the more stable a deck will be, which comes at a higher cost. Here at Pallet Rack Now, we offer 2.5” x 4” mesh – a pretty standard mesh density for wire decking.

Advantages of Wire Decking

Wire decking meets more code requirements than corrugated or flat panels between pallet racking. It provides excellent stability and versatility in pallet rack storage solutions. There is no limit to what you can store with the many styles and channel shapes. No matter the need – may it be sanitary storage or just more flat storage space on your pallet racking – wire decking widens your options.

Pallet supports are different from wire decks. They need to be screwed in. Pallet supports are metal bars that lie in between the pallet rack beams and lend additional support to the structure of the bay, whereas wire decks create a flat surface for storage and cover the entirety of the space in between beams.

Wire Mesh Decking

Though we’ve referred to it as wire decking throughout the majority of this blog, there are many names for this decking – the most common being wire mesh decking. You may also see it referred to as wire shelving, wire panels, steel mesh decking, rack wire, and more.

New and Used Wire Decking For Sale

At Pallet Rack Now, we offer numerous new and used wire decking options in multiple dimensions. Are you looking to buy or sell used wire decks or pallet racking? Visit our page to get a quote today!